Description

Product description

Brief Introduction:

Air end: German Technology. 30 years designed lifetime.

Motor: 100% rare earth permanent magnet motor.

Inverter: Chinese No. 1 inverter can save 30% energy.

Warranty: 5 years for the air end, and 2 years for the whole compressor.

Delivery time: 7-15 days.

After-sales service:we have our professional after-sales technician to instruct the installation of the whole screw air compressor.

We offer free pipe and valves for installation and installation diagram

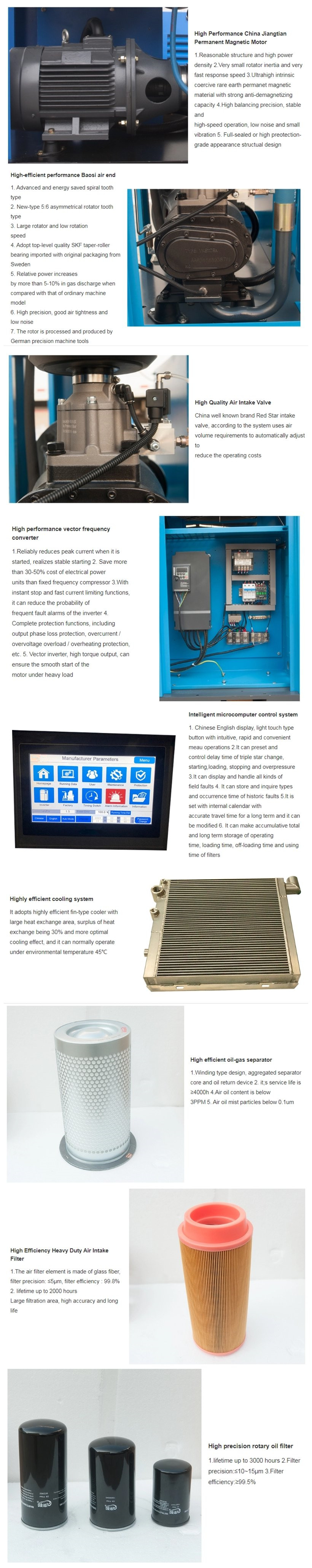

Advantages

1. Air end of screw air compressor

The air end is with state-of-the art screw element and 4 -6 SKF bearings to make sure it plenty of air output and longer lifetime.

2.Electric Motor of the air compressor

Name brand qualified IP54 ,F insulation, IE2 , IE3 motor , high efficiency and energy saving.

3. Intake valve of the screw air compressor

High efficiency intake valve protects the compressor components by removing 99% dirty particles down to 3 microns.

4. Oil Air separator

High efficiency separating for oil and air and low oil content in the compressed air.

5. Touch Screen Controller.

6. High efficient Centrifugal fan can give best cooling for screw compressor.

7.Dust proof mesh to protect electrical control system

Product details

Technical Specifications of screw air compressor

Model

Air Flow (m³/min)

Motor Power

Noise

Outlet Diameter

Dimension

Weight

7bar

8bar

10bar

13bar

kw

dB

inch

W*D*H (mm)

kg

YP-10A

1.1

1.0

0.85

0.7

7.5

65

G1''

960*680*960

280

YP-15A

1.8

1.65

1.5

1.3

11

65

G1''

1050*830*1240

380

YP-20A

2.4

2.2

2.1

1.8

15

68

G1''

1050*830*1240

380

YP-25A

3.1

3.0

2.7

2.3

18.5

68

G1''

1200*830*1290

480

YP-30A

3.8

3.6

3.2

2.5

22

68

G1''

1200*830*1290

480

YP-40A

5.3

5.0

4.3

3.6

30

69

G11/2''

1300*1000*1540

710

YP-50A

6.6

6.2

5.7

4.6

37

69

G11/2''

1300*1000*1540

710

YP-60A

8.0

7.7

6.9

6.0

45

70

G11/2''

1500*1160*1700

990

YP-75A

10.5

9.8

8.7

7.3

55

70

G11/2''

1500*1160*1700

990

YP-100A

13.6

13.0

11.3

10.1

75

72

G2''

1700*1180*1800

1300

YP-125A

16.2

15.4

13.2

11.2

90

72

DN50

1850*1200*1900

1400

YP-150A

20.8

19.5

16.5

13.7

110

73

DN65

2250*1260*2055

1560

Remarks:

1. working ambinent temperature: -5℃-45℃;

2. exhausting air temperature ≤ working ambinent temperature +10℃-15℃;

3. starting mode: Y-△;

4. exhausting oil content: <3ppm;

5. certificate: CE/ISO9001/ASME;

6. voltage: 380V/220V/400V/440V/415V

Our Factory:

1. Starting from 2001;

2. With 8,000sq meters workshop;

3. With 6 production lines;

4. 500pcs production capacity per month

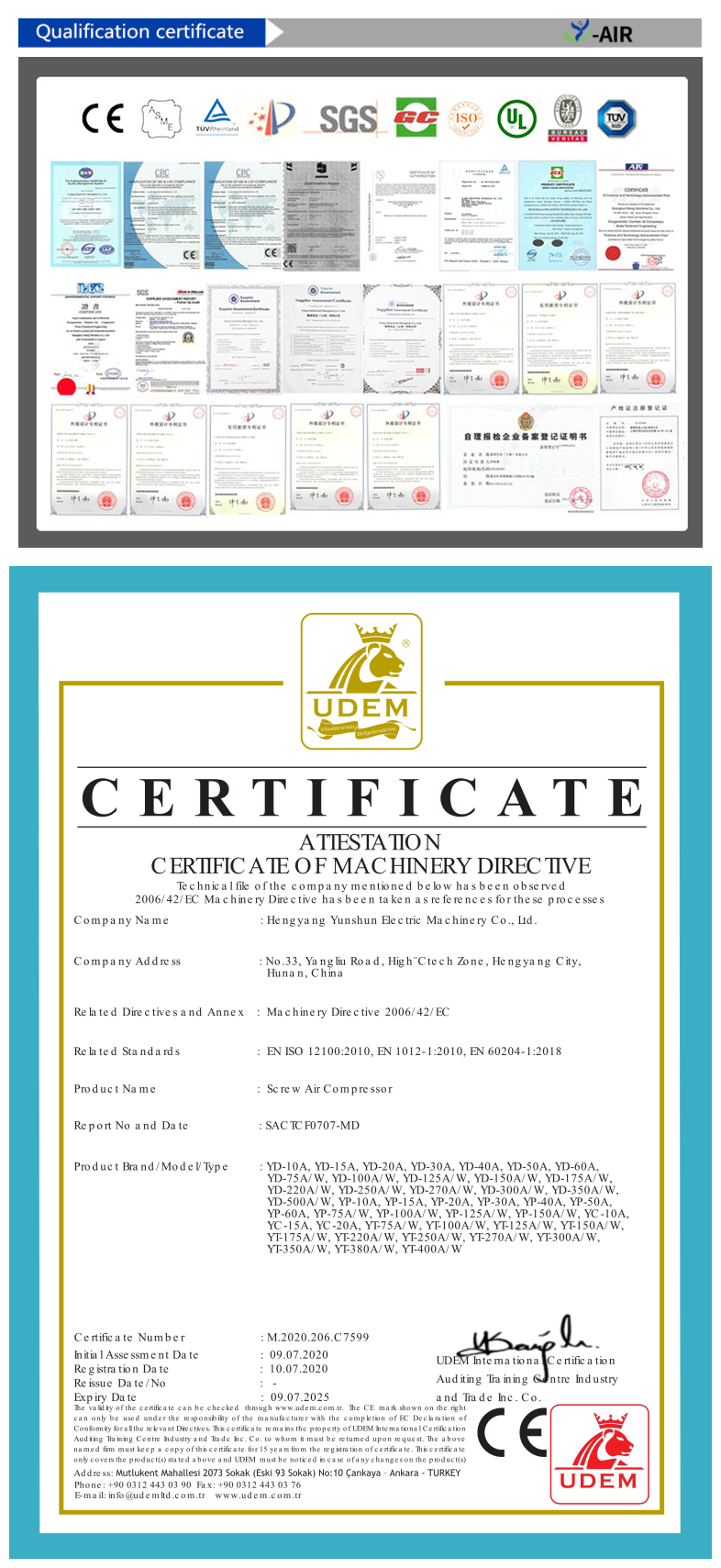

Our Certificates:

1. CE;

2. SGS;

3. ISO9001;

4. 12 patents for screw compressor.

1. Screw air compressors are exported to 132 countries and regions all over the world;

2. All indicators of screw air compressor are stable and the failure rate is low;

3. Perfect after-sales service system, engineers on duty 24 hours a day to provide one-on-one service to customers at the air compressor use site.

Pre-factory quality control process:

1.Installation inspection of the whole air compressor: check and confirm the whole machine according to the operation instructions and quality control standards. Main inspection items:

A . Confirm the nose and motor nameplates;

B . Check whether there is oil leakage in the pipeline and oil circuit of the air compressor; C . the air compressor machine screw locking inspection..

2. air compressor factory test machine, heat engine: test whether the air compressor operation parameters meet the requirements of customers, including voltage, current, working pressure, exhaust volume, etc.Air compressor factory before 48 hours of thermal test, stability confirmation.

3. 24 hours online after-sales service, one-to-one online guidance installation, debugging, troubleshooting.

1. Screw air compressor packaging is divided into three layers from inside to outside:

1) The first layer of protection: spray paint on the surface of the machine to protect the surface of the machine. The fouling pull film is wrapped around the surface of the machine to protect the surface of the paint.

2) The second layer of protection: anti-collision protection of the machine. On the basis of lacquer protection, anti-collision buffer cotton is used to protect the machine against collision.

3) The third layer of protection: the case adopts the overall packaging of the non-fumigation wooden case to protect the machine during transportation.