Description

Product description

Brief Introduction:

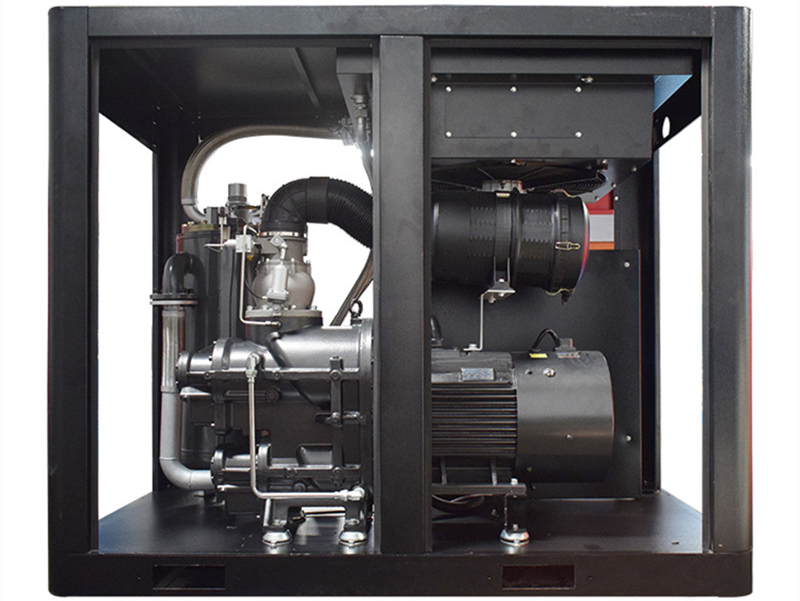

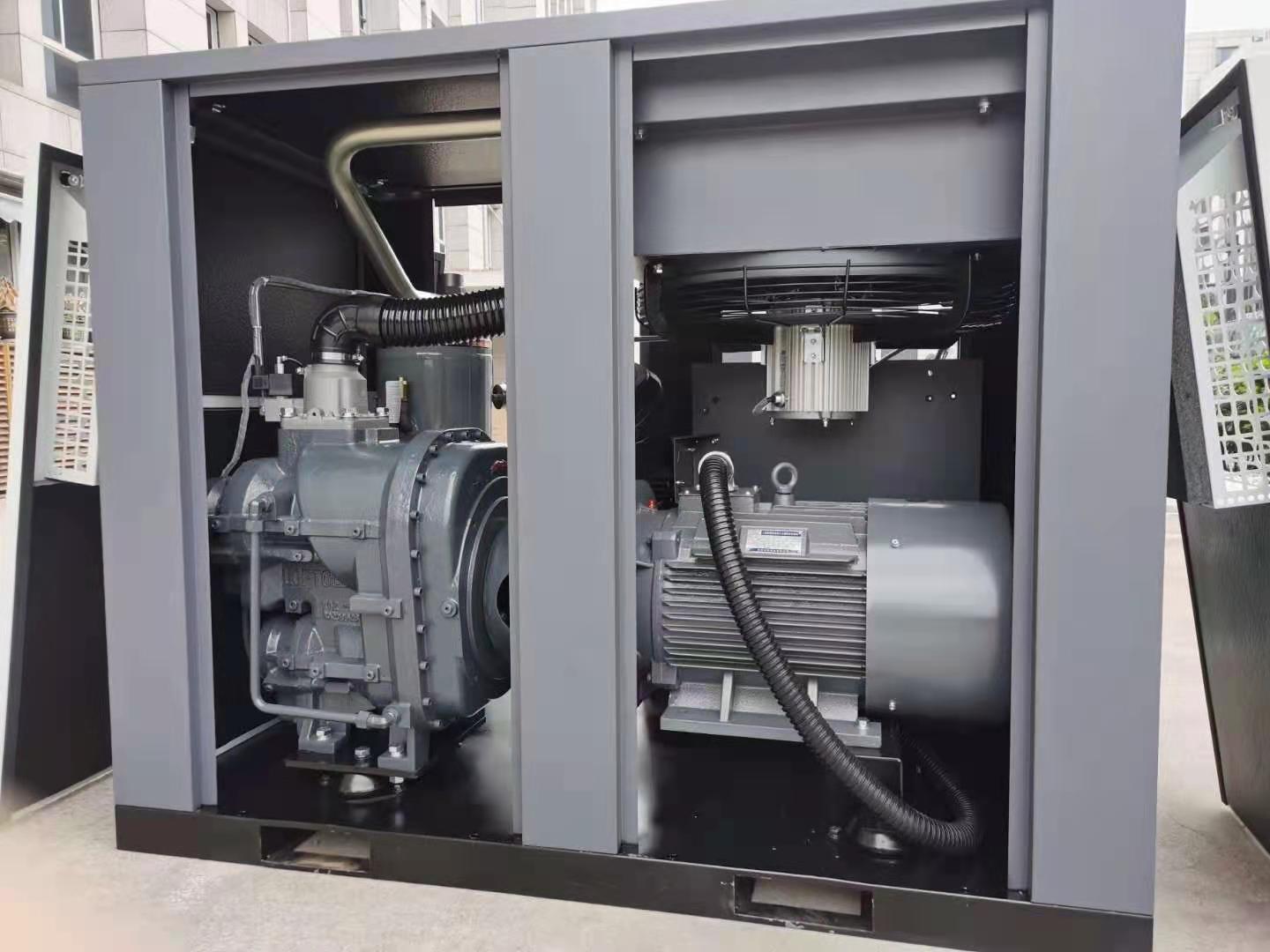

Air end: German Technology. 30 years designed lifetime.

Motor: 100% rare earth permanent magnet motor.

Inverter: Chinese No. 1 inverter can save 30% energy.

Warranty: 5 years for the air end, and 2 years for the whole compressor.

Delivery time: 7-15 days.

After-sales service:we have our professional after-sales technician to instruct the installation of the whole screw air compressor.

We offer free pipe and valves for installation and installation diagram

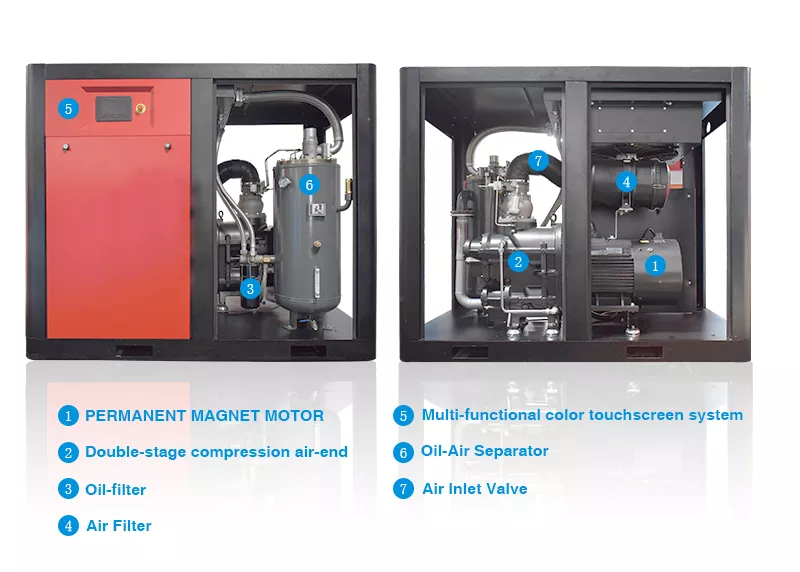

Product details

Technical Specifications of screw air compressor

| Model | Air Flow (m³/min) | Motor Power | Noise | Outlet Diameter | Dimension | Weight | ||||

| 7bar | 8bar | 10bar | 13bar | kw | dB | inch | W*D*H (mm) | kg | ||

| YT-75A | 12.8 | 12.5 | 9.6 | 8.6 | 55 | 70 | RP2'' | 2100*1360*1660 | 2180 | |

| YT-100A | 17.5 | 16.5 | 12.5 | 11.2 | 75 | 72 | RP2'' | 2100*1360*1660 | 2280 | |

| YT-125A | 20.0 | 19.8 | 16.9 | 14.3 | 90 | 72 | DN65 | 2666*1730*1918 | 3200 | |

| YT-150A | 24.5 | 23.5 | 19.7 | 17.6 | 110 | 73 | DN65 | 2666*1730*1918 | 3360 | |

| YT-175A | 30.0 | 28.0 | 23.5 | 19.8 | 132 | 74 | DN80 | 2866*1730*1918 | 3450 | |

| YT-220A | 34.5 | 33.6 | 30.0 | 23.8 | 160 | 75 | DN80 | 2866*1730*1918 | 3850 | |

| YT-250A | 41.0 | 38.5 | 32.5 | 28.6 | 185 | 76 | DN80 | 3200*1780*1918 | 3990 | |

| YT-270A | 44.6 | 43.0 | 38.5 | 32.5 | 200 | 77 | DN100 | 3200*1780*1918 | 5890 | |

| YT-300A | 48.6 | 47.0 | 41.0 | 38.0 | 220 | 78 | DN100 | 4000*1780*1968 | 6500 | |

| YT-350A | 55.0 | 54.0 | 46.0 | 40.0 | 250 | 80 | DN125 | 4200*2120*2200 | 6800 | |

| YT-350W | 55.0 | 54.0 | 46.0 | 40.0 | 250 | 80 | DN125 | 3400*2120*2200 | 6800 | |

| YT-380A | 60.0 | 51.0 | 45.0 | 280 | 83 | DN125 | 4200*2120*2200 | 7200 | ||

| YT-380W | 60.0 | 51.0 | 45.0 | 280 | 83 | DN125 | 3400*2120*2200 | 7200 | ||

| YT-400A | 67.5 | 61.0 | 51.0 | 315 | 83 | DN125 | 4350*2050*2120 | 7800 | ||

| YT-400W | 67.5 | 61.0 | 51.0 | 315 | 83 | DN125 | 3850*2050*2120 | 7800 | ||

| Remarks: | ||||||||||

| 1. "A" represents air cooling, and "W" represents water cooling; | ||||||||||

| 2. working ambinent temperature: -5℃-45℃; | ||||||||||

| 3. exhausting air temperature ≤ working ambinent temperature +10℃-15℃; | ||||||||||

| 4. starting mode: Y-△; | ||||||||||

| 5. exhausting oil content: <2ppm; | ||||||||||

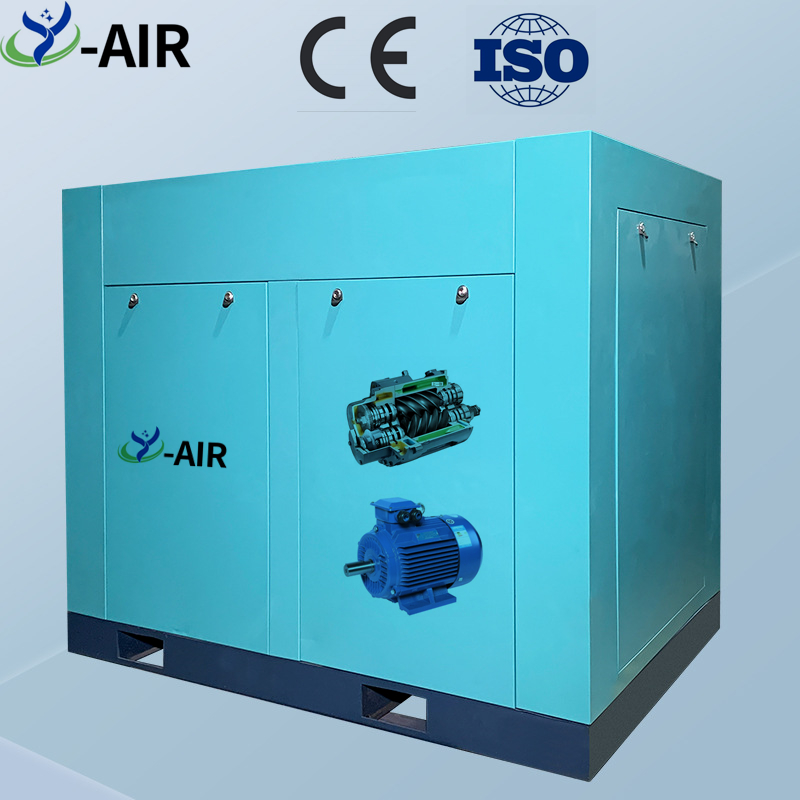

| 6. certificate: CE/ISO9001/ASME; | ||||||||||

| 7. voltage: 380V/220V/400V/440V/415V | ||||||||||

Our Certificates:

1. CE;

2. SGS;

3. ISO9001;

4. 12 patents for screw compressor.

1. Screw air compressors are exported to 132 countries and regions all over the world;

2. All indicators of screw air compressor are stable and the failure rate is low;

3. Perfect after-sales service system, engineers on duty 24 hours a day to provide one-on-one service to customers at the air compressor use site.

Pre-factory quality control process:

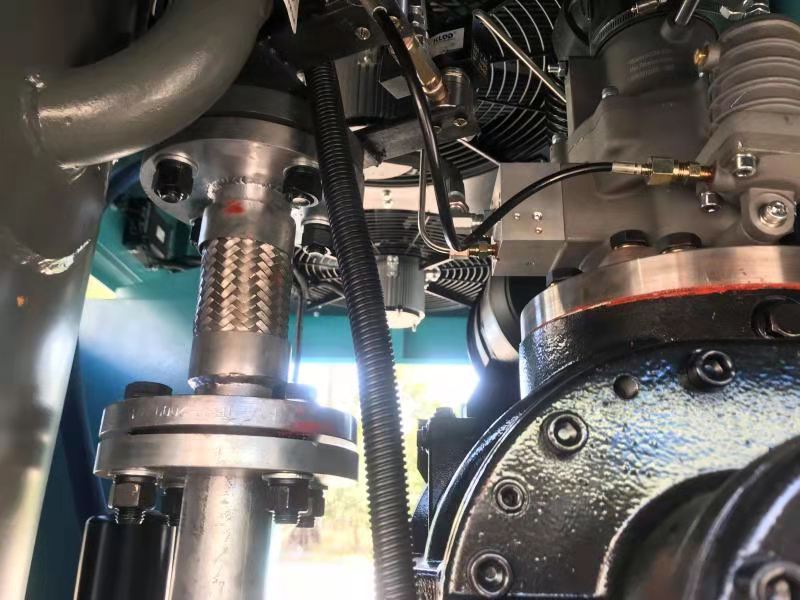

1.Installation inspection of the whole air compressor: check and confirm the whole machine according to the operation instructions and quality control standards. Main inspection items:

A . Confirm the nose and motor nameplates;

B . Check whether there is oil leakage in the pipeline and oil circuit of the air compressor; C . the air compressor machine screw locking inspection..

2. air compressor factory test machine, heat engine: test whether the air compressor operation parameters meet the requirements of customers, including voltage, current, working pressure, exhaust volume, etc.Air compressor factory before 48 hours of thermal test, stability confirmation.

3. 24 hours online after-sales service, one-to-one online guidance installation, debugging, troubleshooting.

Air compressor packing method

1. Screw air compressor packaging is divided into three layers from inside to outside:

1) The first layer of protection: spray paint on the surface of the machine to protect the surface of the machine. The fouling pull film is wrapped around the surface of the machine to protect the surface of the paint.

2) The second layer of protection: anti-collision protection of the machine. On the basis of lacquer protection, anti-collision buffer cotton is used to protect the machine against collision.

3) The third layer of protection: the case adopts the overall packaging of the non-fumigation wooden case to protect the machine during transportation.